High-Pressure Mixer Washout System

The Safe, cost-effective way to clean concrete mixers

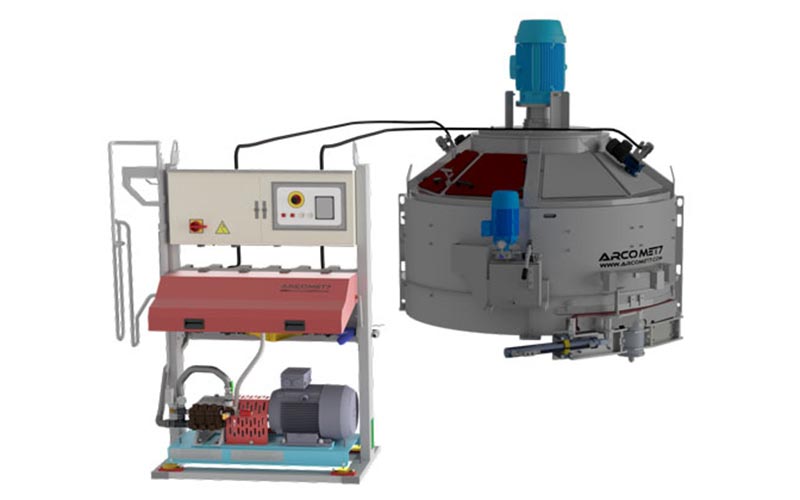

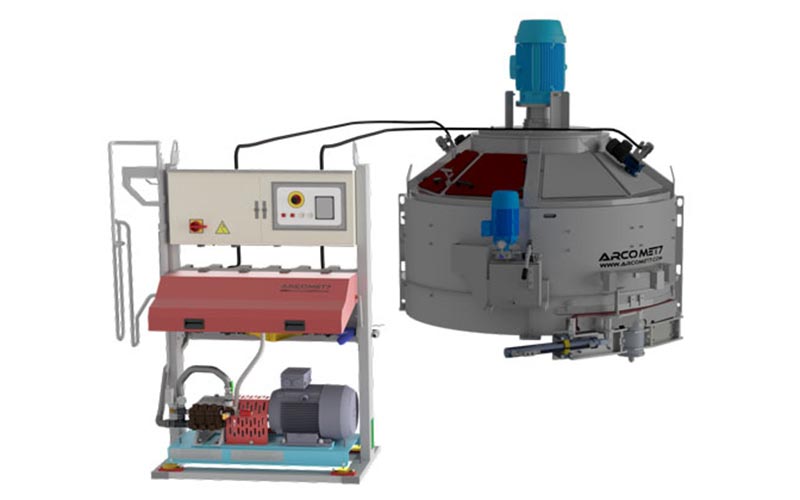

Our unique standalone high-pressure mixer washout systems are capable of cleaning concrete mixers after the production cycles safely, quickly, and cost-effectively. The system is supplied as a single plug-and-play package and is designed for simple retrofitting to any make of concrete plants available on the market.

High Pressure Mixer Washout System

This unique standalone High-Pressure Mixer Washout System is capable of cleaning concrete mixers after the production cycles safely, quickly and cost effectively. The system is supplied as a single plug-and-play package and is designed for simple retrofitting to any make of concrete plants available on the market.

The system comprises:

- A motor driving a high-pressure water pump.

- A separate control system, with safety switches.

- Washing heads (to be installed on the mixer body)

- A manual washing lance.

Keep your personnel safe

Getting inside concrete mixers needs the highest level of training and safety awareness for your Operators and Safety Personnel. The risk of both short- and long-term injury is high with the regulations for working in confined spaces constantly changing, requiring additional investment.

Our system eliminates the need for people getting into mixers and offers a cost effective, efficient solution to cleaning mixers. As an added bonus our system can prolong the service life of your concrete mixer. Contact us today for a free assessment to see if we can help you minimise risk and improve the efficiency of your operation.

Keep your personnel safe

Getting inside concrete mixers needs the highest level of training and safety awareness for your Operators and Safety Personnel. The risk of both short- and long-term injury is high with the regulations for working in confined spaces constantly changing, requiring additional investment.

Our system eliminates the need for people getting into mixers and offers a cost effective, efficient solution to cleaning mixers. As an added bonus our system can prolong the service life of your concrete mixer. Contact us today for a free assessment to see if we can help you minimise risk and improve the efficiency of your operation.

Exceptional Cleaning with RH-400 Rotary Heads

RH-400 Rotary Heads have been specifically designed for high-pressure washing applications. The nozzles on the head cover a wide-angle and eliminates blind spots.

Washing cycles automatically switch from one rotary head to another ensuring stable, high-pressure washing in all areas of the mixer.

Prolonged Life time and Reduced Costs

Demolition hammers can damage bearings and gearboxes whilst placing additional stresses on the mixer body and paddles. The process can be very expensive when you consider the additional costs incurred through loss of production and service parts.

By using our high-pressure mixer washout system, you can get all these benefits:

- No human entry into the mixer

- Reduced risks

- Safer operation

- Reduced down-times for cleaning

- No additional costs for cleaning from the inside

- Longer service life of the equipment

Prolonged Life time and Reduced Costs

Demolition hammers can damage bearings and gearboxes whilst placing additional stresses on the mixer body and paddles. The process can be very expensive when you consider the additional costs incurred through loss of production and service parts.

By using our high-pressure mixer washout system, you can get all these benefits:

- No human entry into the mixer

- Reduced risks

- Safer operation

- Reduced down-times for cleaning

- No additional costs for cleaning from the inside

- Longer service life of the equipment

Environmentally Friendly Washing

Our system can calculate the amount of the wash water used by integrating the flowmeter into the batch computer system. It ensures that the water, used for washing, stays in the mixer and is ready for the next batch. This process uses less water to top up the recipe for the next batch and reduces waste.

Bulldog are here to help

The Bulldog team are on-hand to help find the right solution for your project.

Please call us on 01371 873282 or send us your enquiry.